Battery Fire Containment Blanket for Lithium-Ion and HV Batteries

The HV Battery Fire Containment Blanket is an advanced fire protection solution for the safe handling of lithium-ion, HV, and traction batteries. It has been specifically developed for preventive fire protection in industrial environments and is used wherever high-performance batteries pose a potential risk.

Especially in the event of a thermal runaway – an uncontrolled reaction of lithium-ion cells – the blanket prevents the rapid spread of heat, flames, and smoke gases. This reliably protects surrounding areas and significantly increases the safety of employees, equipment, and materials.

Made from extremely high temperature-resistant silica glass fabric, the HV Battery Fire Containment Blanket withstands even extreme conditions. It is suitable for both the storage and transport of batteries as well as for emergency use when immediate protection is required.

With its robust design and special material composition, it provides a reliable safety barrier for companies in the automotive industry and all sectors where HV and traction batteries are used.

| Material | Silica Glass |

| Coating | Double-Sided Vermiculite |

| Continuous Temperature Resistance | up to 1200 °C |

| Short-Term Peak Load | up to 1600 °C |

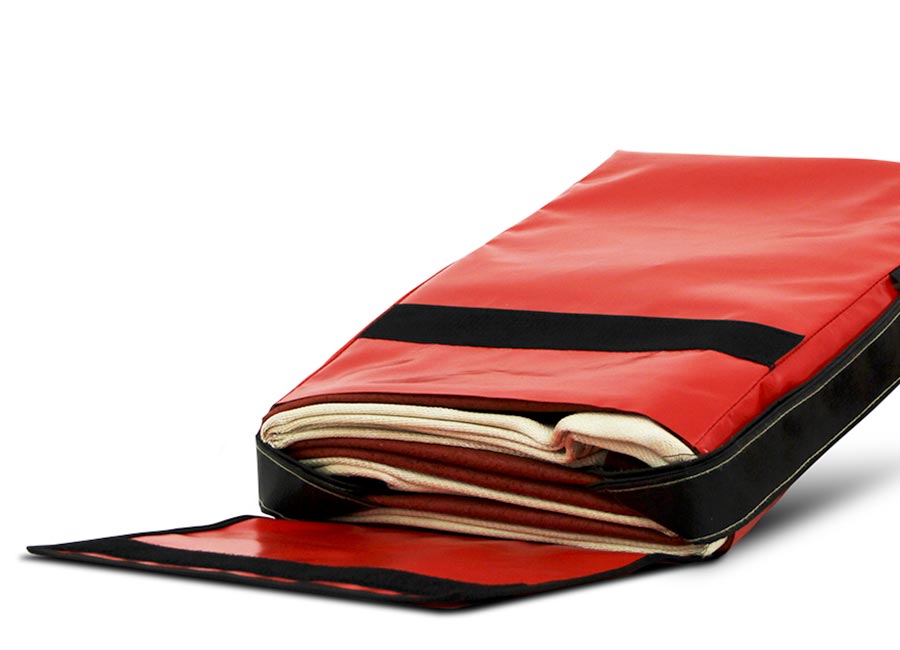

| Packaging | In durable PVC bag for wall mounting – optionally also available in a mobile trolley |

| Fire Behavior | Tested according to DIN EN 13501-1 |

| Electrical Behavior | Non-conductive, tested according to DIN 54345-1 |

Technical Characteristics

- Extremely high temperature resistance: Our fire protection covers for HV and traction batteries are designed for continuous exposure up to 1000 °C and short-term peak temperatures up to 1200 °C.

- Thermal protection effect: Delay or containment of flame spread, sparks, and hot particles in the event of thermal runaway or cell failure.

- Emergency response: Increases reaction time in the event of fire incidents and enables controlled emergency measures (e.g. evacuation, fire containment).

- Barrier effect: Formation of a thermally stable protective zone around the battery system – protection for adjacent components, work areas, and infrastructure.

- Reduction of escalation risks: Ideal for risk mitigation in in-house storage, logistics, and series production.

- German manufacturing: Development, production, and quality control – 100% Made in Germany.

Application Examples

- Incidents & emergency management: Fast response to battery fires or thermal events in production or storage environments.

- End-of-line tests: Securing HV and traction batteries during final testing processes and quality inspections.

- Recycling & dismantling: Fire protection measure during the disassembly and processing of lithium-ion batteries.

- In-plant transport: Additional protective barrier during internal battery transport between assembly, testing, and storage.

- Hazardous materials and test laboratories: Use in specialized environments with increased fire risk from lithium-ion systems.

- Research & development: Protective solution for tests, simulations, and prototype setups in laboratory and development environments.

- Training & education environments: Demonstration and practical handling of thermal runaway scenarios under controlled conditions.

Similar products