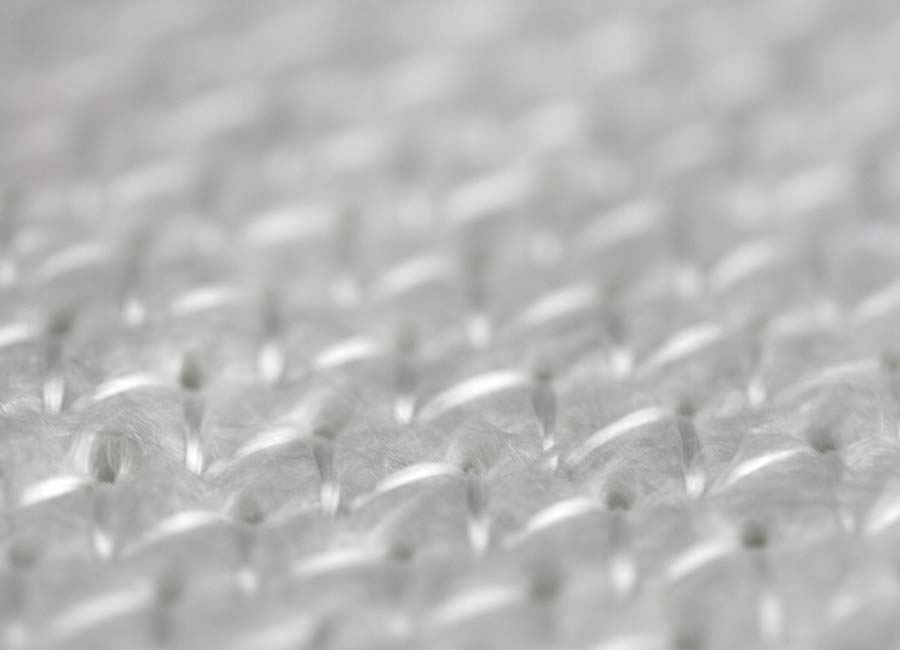

Glass Fiber Stitch-Bonded Needle Mats

Glass Fiber Stitch-Bonded Needle Mats are specifically developed for use in thermally and mechanically highly stressed environments, offering versatile applications for the insulation market. They are characterized by excellent strength and dimensional stability at application temperatures of up to 1000+ °C. A precise manufacturing process converts multi-layer glass fibers into high-performance mats that can be optimally used in industrial applications for thermal insulation as well as in insulation and heat protection systems.

The glass fiber stitch-bonded needle mats are produced using a special process that is purely mechanical and without the addition of binders from high-quality E-glass fibers. In addition, they are interwoven with a yarn, giving the mats exceptionally high strength. This interweaving significantly improves the dimensional stability and strength of the mats.

| Weight | 450 - 2900 g/m |

| Thickness | 3 - 12 mm |

| Standard width | 1000 mm |

| Production width | up to 2000 mm |

| Roll length | 15 to 50 m/roll (depending on material thickness) |

| Filament diameter | ≥ 6 μm |

| Optional coatings | Aluminum foil (A), Self-adhesive foil (SK) |

High-Performance Fiberglass Stitch-bonded Needle Mats – Our Trusted Standard Grades

For information on additional grades or our customized coating options, feel free to contact us.

| Quality type | Fiber type | Temperature resistance | Weight | Thickness | Standard Width | Data Sheet |

|---|---|---|---|---|---|---|

| isoFLEX® 600/NG | E-glass fiber | 600 °C | 600 - 2900 g/m² | 4 - 12 mm | 1000 mm | |

| isoFLEX® 800/NG | HR-glass fiber | 800 °C | 600 - 2900 g/m² | 4 - 12 mm | 1000 mm | |

| isoFLEX® 1100/NG | Silica glass fiber | 1100 °C | 600 - 2900 g/m² | 4 - 12 mm | 1000 mm |

Technical Characteristics

- Permanent application in environments with temperatures up to 800 °C.

- Glass fiber stitch-bonded needle mats ensure high tensile, compressive, and flexural strength in all directions. This allows for use in areas with high mechanical requirements.

- Thanks to the consolidated structure, the glass fiber layers remain fixed even under mechanical stress, minimizing deformations or fiber migrations.

- Glass fiber is extremely resistant to chemical influences, providing a long service life even in aggressive environments.

- Stitch-bonded needle mats made of glass fiber are lightweight and offer an excellent weight-to-performance ratio.

Application Examples

- Glass fiber stitch-bonded needle mats are used for the insulation of high-temperature furnaces and equipment to minimize heat loss and increase energy efficiency.

- They are used as fire protection materials in the automotive and aerospace industries to enhance protection against flames and high temperatures.

- Glass fiber stitch-bonded needle mats protect other components in the engine compartment from overheating.

- Glass fiber stitch-bonded needle mats provide electrical insulation in transformers and electric motors.

- They are used for the insulation of pipelines in chemical and petrochemical plants to maintain the temperature of the flowing media.

- They are used in chemical reactors to withstand extreme temperatures and aggressive chemicals.

- In the insulation of storage tanks for chemical substances, they provide protection against temperature fluctuations.

Similar products