Fingerhuth® HeatProtection

Isolier- und Textiltechnik Fingerhuth

Vulkanhof 1 - 56651 Niederzissen - Germany

Phone: +49 (0) 2636 970227

E-Mail: info@heatprotection.de

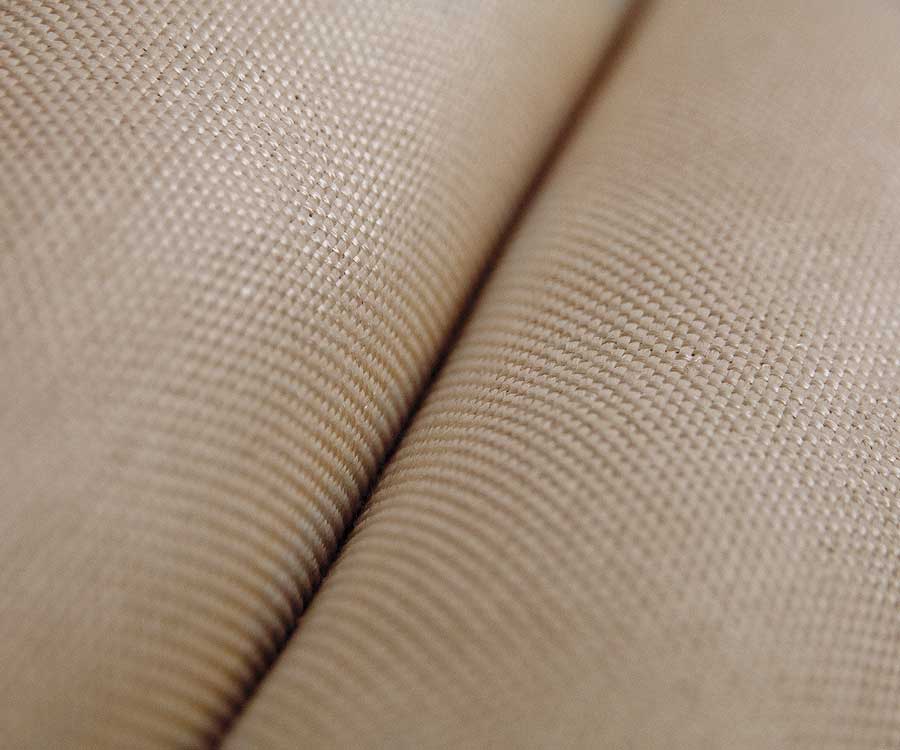

isoTEX® E-Glass Fiber Fabric, Heat Treated / Caramelised

600.T

Material specification:

E-Glass Fiber

Treatment:

Heat Treated (T)

Application temperature:

up to 550 °C

Qualities:

200 - 1000 g/m²

Heat treated or caramelized glass fabric is made from standard woven glass fibers and undergone an additional finishing stage in which the fabric is passed through a high temperature oven. This process burns off the small amount of weaving oils and lubricants (sizing) present on standard fiberglass yarns. This procedure can also help remove surface fibers, which can help reduce irritation from handling.

This process results in the light brown or "caramel" color of the fabric. Caramelised glass fabric is often specified when fumes or “outgassing” cannot occur during the final products first heat cycle, or in some applications where the weaving oils and lubricants may interfere with adhesion to other products.

We would be happy to advise you personally on this.

600.T

(up to 550 °C)

Technical Specifications

| Material specification: | E-Glass fiber |

| Application temperature: | up to 550 °C |

| Application limit temperature: | approx. 600 °C |

| Manufacturing qualities: | 200 - 1000 g/m² |

| Manufacturing widths: | 1000 - 2000 mm |

| Treatment: | Heat Treated / Caramelised (thermally desized) (T) |

| Colour: | brown-beige (caramel colored) |

Technical Characteristics

- Temperature resistance up to 550 °C, short term up to 600 °C

- Small proportion of sizing agent and lubricant

- No outgassing on first use

- Good thermal stability

- Solvent and halogen free

- Absolutely harmless to health, not subject to classification (NOT a hazardous substance)

Application Examples

- Generally as a heat protection and insulating fabric for industrial applications

- Steel industry

- Mechanical and plant engineering

- Thermal insulation and covers

Deutsch

Deutsch

English

English